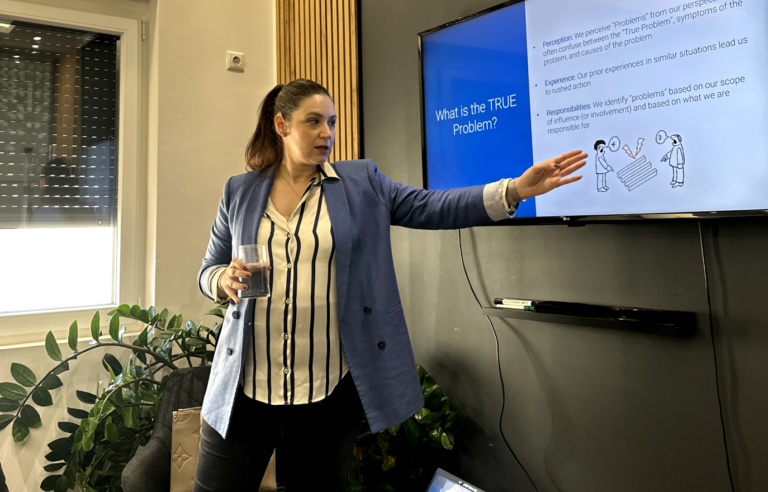

Continuing our commitment to fostering knowledge-sharing and professional growth, AnchorzUp welcomed Iva Kodhelaj, Director of Growth Initiatives – Commercial Excellence at Sonova Group, as the esteemed speaker for our second Guest Lecture Series.

With over a decade of experience in Commercial Excellence and global process improvements, Iva brought a wealth of knowledge and insights. Her impressive career includes a Computer Science & Business Administration foundation, and she has successfully founded and scaled a Process Center of Excellence at a $20 billion/year company.

The session focused on Lean Management, a methodology aimed at maximizing value while minimizing waste. Iva broke down the core aspects of Lean into three key sections:

- Lean Fundamentals – Highlighting the core philosophy behind Lean management.

- Lean Principles – Emphasizing the importance of eliminating waste and focusing on value-added activities.

- Lean Tools – Diving deep into the A3 Problem-Solving Tool, a structured approach for continuous improvement.

Although Iva is a strong advocate of the 1% Marginal Gains concept—the idea that small, incremental improvements can lead to remarkable overall success—her presentation delivered far more than just 1% gains for our team. With every slide and insight, she offered invaluable tools and perspectives to elevate our understanding of Lean Management and process improvement.

Here are the 5 key lessons from Lean Management shared by Iva during the session:

- Eliminate Waste (Muda) – The core principle of Lean is to identify and eliminate waste in all its forms. This includes overproduction, waiting times, unnecessary transportation, excess inventory, unnecessary motion, defects, and over-processing. By reducing waste, organizations can improve efficiency and focus on activities that add value.

- Focus on Value – Lean encourages organizations to define what value means from the perspective of the customer and focus on activities that directly contribute to that value. This ensures that every process, step, and resource is aligned with customer needs and expectations.

- Continuous Improvement (Kaizen) – Small, incremental improvements over time can lead to significant gains in productivity and quality. Employees at all levels are encouraged to contribute ideas and participate in improving processes.

- Standardize Processes – Create consistency to reduce variation and improve efficiency. Once a process is standardized, it becomes easier to identify inefficiencies and areas for improvement, which leads to more streamlined operations.

- Empower Employees – Lean management values the input and engagement of employees at all levels. By empowering teams to take ownership of their work, suggest improvements, and participate in problem-solving, organizations foster a culture of accountability and innovation, which leads to better outcomes.

To wrap up her presentation, Iva shared actionable tips and tricks, key takeaways, and practical insights from her years of experience. The session concluded with an engaging Q&A, where our team explored ways to implement Lean principles in real-world scenarios.

This Guest Lecture Series exemplifies AnchorzUp’s dedication to learning and growth, providing our team with direct access to industry leaders and innovative ideas.

We’re grateful to Iva for sharing her expertise and inspiring us to think critically about how we can enhance processes, drive efficiency, and create lasting value.

Stay tuned for the next session in our Guest Lecture Series!